In Wood We Trust

Building a Sustainable, Equitable Future With Circular Economies

We trust in wood (specifically, in low‑grade woody biomass) to power a future that is cleaner, fairer, and more resilient. By turning locally available forest residuals into drop‑in, low‑carbon gasoline and high‑value co‑products, we can accelerate decarbonization without forcing costly, disruptive changes to vehicles, infrastructure, or communities. This is the promise of circular economies in action: reduce, reuse, recycle, and repair, closing loops while opening opportunity.

“In Wood We Trust” nods to the American motto and the reliability of wood-based solutions, reflecting our belief in sustainable forestry, local prosperity, and practical decarbonization.

Why “In Wood We Trust”

Because wood is regenerative, abundant, and familiar. Because smart forestry and smart chemistry can swiftly decarbonize transportation, without asking families or first responders to change vehicles, routes, or routines. Because local feedstocks, local jobs, and local fuels knit communities closer together while cutting carbon.

Trust in wood is trust in a circular future, designed around what works, where we live.

Why Wood Works: Abundant, Renewable, Local

Pennsylvania’s hardwood forests are abundant, managed for regeneration, and currently growing roughly twice as fast as they’re harvested and decayed, yet they face a “sea of sameness” from even‑aged stands.

Sustainable forestry needs strong markets for low‑grade material (tops, bark, small‑diameter stems) to fund habitat improvements and mixed‑age mosaics.

Low‑grade utilization is the missing economic link. Converting residuals into sustainable vehicle fuels (SVFs) makes forest health work commercially viable, supporting biodiversity, resilience, and long‑term timber quality.

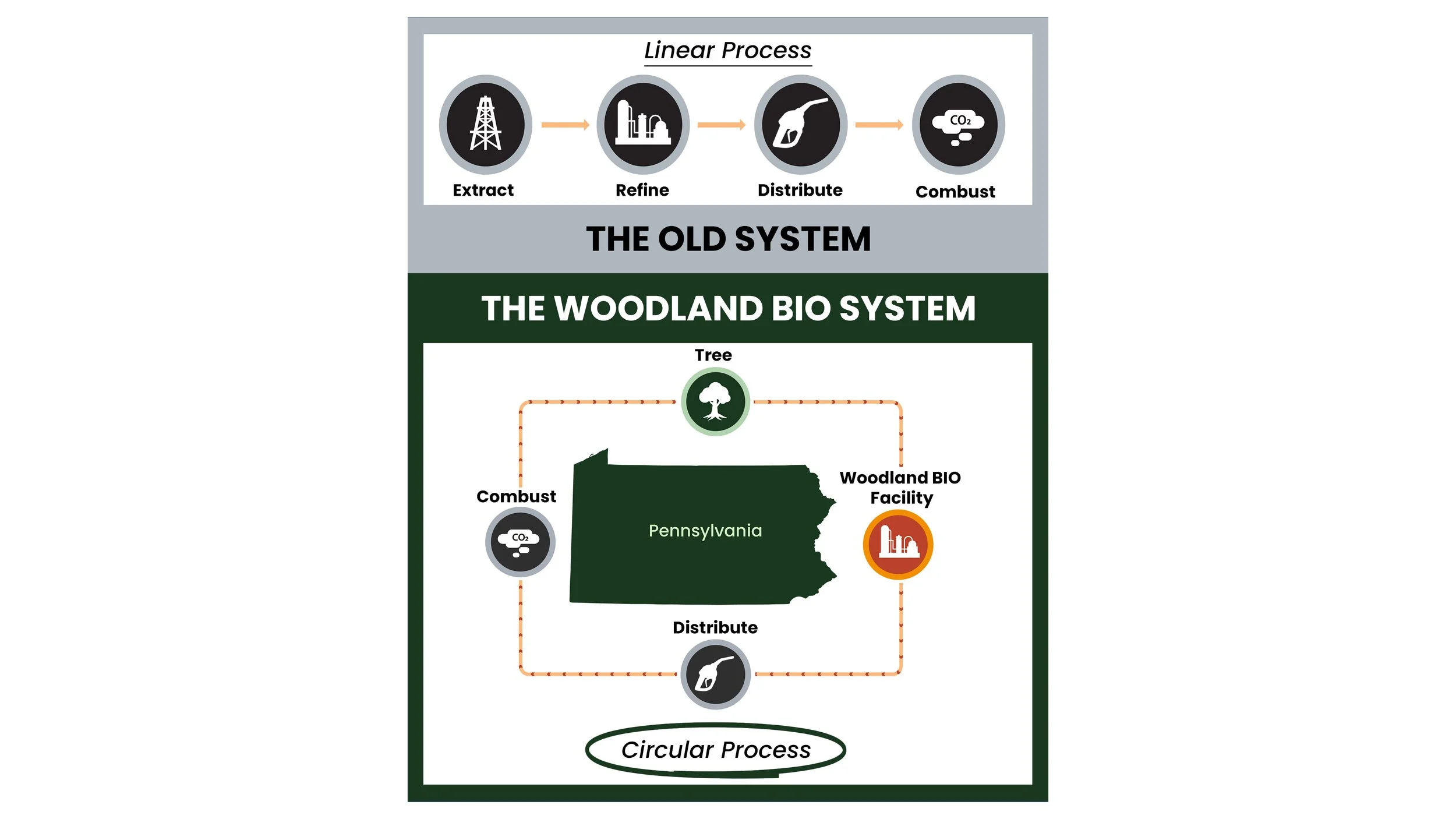

From Linear To Circular: Keep Carbon Cycling, Keep Value Local

Traditional fuel supply chains are linear: extract → refine → burn → emit. Circular systems keep materials and value in motion. By converting regional woody biomass into low‑carbon gasoline, biochar, and renewable electricity, we:

Reduce greenhouse gas emissions versus fossil pathways

Localize energy revenue, creating durable main‑street jobs

Improve forest outcomes by monetizing low‑grade wood

Build regional resilience against global supply shocks

In real terms, every dollar you spend on local, sustainable gasoline recirculates through jobs in forestry, operations, logistics, and local services, instead of leaving the community.

Drop‑In Sustainable Gasoline: Decarbonize Today, No New Hardware Tomorrow

Sustainable Vehicle Fuels (SVFs) are “drop‑in” fuels that are chemically compatible with existing engines and distribution. Our gasoline:

Meets and exceeds U.S. RBOB specifications

Has a zero‑sulfur, zero‑benzene profile

Works in every gasoline car: mix and match with conventional gasoline anywhere

Moves through today’s pipelines, terminals, and pumps

That means drivers, fleets, and emergency services can cut carbon now: no new vehicles, no charging buildout, no operational compromises.

How It Works: Proven Tech, Smarter Integration

Gasification converts woody biomass into syngas.

Gas‑to‑Liquids (GTL) upgrades syngas into high‑quality gasoline.

Co‑generation and heat integration improve efficiency, while biochar and renewable electricity become valuable co‑products.

These are proven industrial processes, optimized for modern feedstocks and regional supply chains.

Biochar: The Carbon‑Smart Co‑Product With Real‑World Uses

Biochar is pure, stable carbon with powerful applications:

Fertilizer and soil health: improves water and nutrient retention, reduces NPK needs

Animal feed and bedding: can lower methane emissions and capture ammonia

Environmental remediation: binds heavy metals, filters water/wastewater

Industrial decarbonization: partial coke replacement in steelmaking

Low‑carbon construction: concrete and road additives for strength and pollutant capture

Every ton of biochar locks carbon away long‑term while delivering measurable agronomic and industrial benefits.

EVs And The Hybrid Path Forward: Use Every Tool We Have

Electric vehicles are part of the solution, but not the only one. A balanced pathway accelerates decarbonization faster:

Manufacturing footprint: Third‑party LCA data (e.g., Polestar) show EVs start with ~63% higher manufacturing emissions than comparable ICE vehicles.

Clean electricity dependency: EV climate benefits scale with grid cleanliness; many regions still rely heavily on fossil generation.

Battery constraints: Rapid EV scaling strains lithium, cobalt, and nickel supply chains and raises end‑of‑life recycling challenges.

Infrastructure and standards: Charging access, fast‑charge compatibility, and grid capacity remain uneven.

Market reality: Consumer price sensitivity, range confidence, and charging convenience affect adoption; automakers have adjusted EV rollouts as demand ebbs and flows.

Conclusion: Use EVs where they shine—and deploy drop‑in, low‑carbon fuels everywhere else to cut emissions immediately, at scale.

Community Impact: Jobs, Pride, And Regional Prosperity

A commercial‑scale facility can:

Create 50–100 well‑paid direct jobs, plus substantial indirect employment

Channel new revenue to forest operators and landowners for sustainable maintenance cuts

Keep fuel dollars circulating locally instead of exiting the region

Strengthen rural economies with durable, future‑proofed industries

This is how circular economies turn “waste” into wealth, resilience, and shared prosperity.

Forest Stewardship, Backed By Stakeholders

Sustainable low‑grade markets empower forest managers to do what the land needs—today and for generations. Public agencies, industry groups, and community leaders recognize that pairing forest health with viable markets is essential to long‑term ecological and economic success.

FAQs

What makes Woodland BIO’s model “circular,” not linear? We convert low-grade woody residuals into drop-in gasoline, biochar, and renewable electricity, keeping carbon and value cycling locally instead of extract–refine–burn–emit. Co-products are reinvested (biochar in soils/industry), further closing loops.

How does this strengthen local economies and equity? Fuel dollars stay in-region, supporting forestry, operations, logistics, and main‑street services. Facilities create 50–100 direct jobs plus indirect employment, new revenue for landowners, and resilient local tax bases, benefits that typically leak out in fossil supply chains.

How do forest practices fit a circular economy? Sustainable silviculture removes low‑grade material (tops, bark, small stems) to fund habitat improvements and mixed‑age mosaics. Monetizing residuals makes stewardship commercially viable, supporting biodiversity and long‑term timber quality while using renewable, regenerating feedstock.

Why is biochar central to circularity? Biochar locks carbon for the long term and creates multiple value loops: soil fertility (reduced NPK, better water retention), animal systems (lower methane, capture ammonia), remediation, steel decarbonization (partial coke replacement), and low‑carbon construction, turning a byproduct into climate and economic value.

How does this improve regional resilience and reduce risk? Local feedstock + multi‑year price contracts stabilize input costs; drop‑in fuel uses existing vehicles and infrastructure (no new hardware); diversified revenues (fuel, RINs, biochar, electricity) buffer markets. Communities are less exposed to global supply shocks and grid/charging constraints, accelerating near‑term decarbonization.

Join Us on This Journey

We invite you to follow our progress and engage with us as we explore the potential of biomass-to-fuel technology on social media! You can find us on LinkedIn, Facebook, & Instagram.

If you are interested in investing in Woodland BIO follow this link: https://www.woodlandbio.com/invest